THE SHIP's KNEE - MH7

Research Question

Is the ship's knee MH7 from the wreck of HMAS Patricia Cam?

Methodology

Comprehensive Hi Res imaging - laser mapping of artefact.

Document find site recollections, images, geology and remote imagery.

Inquire if Rangers or others have found any similar wreckage.

Wood sample by Jugo Illic Know Your Wood - to identify genus, species and distribution.

Inspection by appropriate marine architects & shipbuilders - to identify location & orientation in vessel of similar period & construction.

Examination of iron fixings by suitably qualified individuals.

Forensic examination via the application of diagnostic techniques - preferably non-invasive.

Return to find site to search for other wreckage - metal detector survey as fixings fall out of burnt or white ant affected timber.

Document find site recollections, images, geology and remote imagery.

Inquire if Rangers or others have found any similar wreckage.

Wood sample by Jugo Illic Know Your Wood - to identify genus, species and distribution.

Inspection by appropriate marine architects & shipbuilders - to identify location & orientation in vessel of similar period & construction.

Examination of iron fixings by suitably qualified individuals.

Forensic examination via the application of diagnostic techniques - preferably non-invasive.

Return to find site to search for other wreckage - metal detector survey as fixings fall out of burnt or white ant affected timber.

Background

The knee was found by senior PastMasters Archaeologist, Michael Hermes, on the last day of the 2013 Ancient Coins in Arnhem Land Expedition to the Wessel Islands. It was stranded at the high energy end of a beach on the western side of Marchinbar Island. The only documented loss of a timber vessel in the general area is that of HMAS Patricia Cam in 1943 - research revealed, on the RAN website, an aerial image of the survivors and critical analysis of the image established the location and a potential grave site with vertical marker - probably a canoe paddle.

Consideration

The knee is from a ship. It was not dislodged violently - the fixing rods have rusted through to a central point. The rods, washers & nuts are right for HMAS Patricia Cam and wrong for SE Asian origin. Wood analysis says the timber is Aglaia of SE Asian origin, not from coastal NSW. The metal is right but the wood is wrong.

Current Hypothesis

|

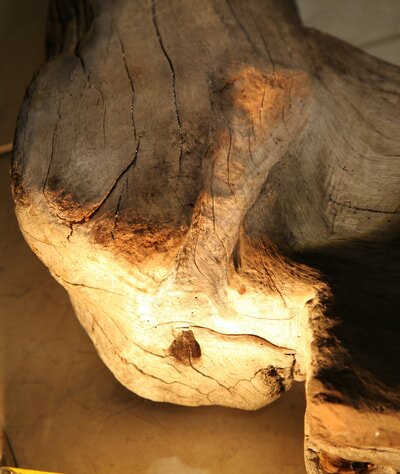

MH7 was inspected by John Setttree in 2018. He is SE coast of NSW fisherman and member of renowned Settree family from Davistown on Brisbane Water who worked on building the Patricia Cam. John offered an alternative to the Beam Knee hypothesis principally founded on the rounding of the heel to accommodate the abrupt curve of the hull to a flat bottom. This inversion of the element would also be the more common orientation for a piece made of trunk & root that is especially strong and so suited to the junction of the keel with the stem or stern posts.

In 2020, a review of the expedition artefacts suggested that the notch on the inside of the ankle - rust-free bore hole, unused fixing holes, heel notch and other excavated timber which is of foreign origin could be explained by the addition of an especially robust floor to the hold - described as a 'double bottom'. Such a floor is essential as the Pat Cam was the fist collier in Australia to be fitted with the mechanical grab. The marine architect 'Ali' Barber was further frustrated by the a variation to allow for a freezer compartment should the Cam family wish to use her as a mother ship for it's fishing fleet.

|

Barber is known to have imported timber from New Zealand. As the variations were necessarily robust but not structural, he may well have accessed and repurposed second-hand material from a Sydney breakers yard.

The location of the timber in the hold would expose it to coal dust and to flying debris impacting the side that faced the explosion that sank the vessel. It would also allow the fixings to rust through and the element to float or move away from the vessel to be rolled along the sea floor and deposited on the strand line by wave action.

The location of the timber in the hold would expose it to coal dust and to flying debris impacting the side that faced the explosion that sank the vessel. It would also allow the fixings to rust through and the element to float or move away from the vessel to be rolled along the sea floor and deposited on the strand line by wave action.

Description

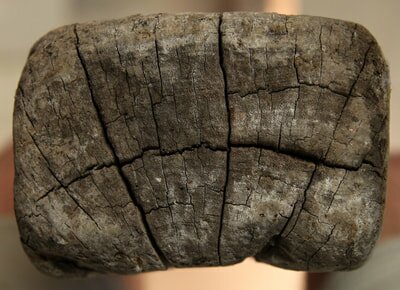

Michael Hermes & MH7

Michael Hermes & MH7

The piece is 'trunk and root' which provides a deeper throat & so greater strength than 'trunk & branch'. These were used in areas of high stress - notably in the Stem & Stern knees which attach the stem & stern posts to the keel.

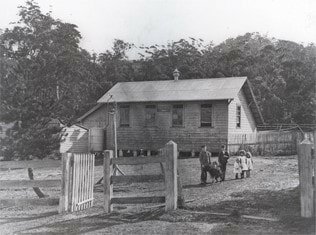

The knee appears to have been partially dressed, perhaps by a power saw - the Beattie Yard had electricity with one saw and one drill.

Beattie's coastal woodland probably depleted. The Pat Cam's naval architect, Arthur Carlyle 'Ali' Barber, imported timber from New Zealand - a bankruptcy petition was brought against him by the Parker Lamb Timber Co. Ltd. of Onehunga NZ for non-payment of accounts on 7 March 1939.

Noel Riley’s observation “a beam knee & not a lodging knee because one of the arms is too long to sit between beams”.

This is not a lodging knee – the beams run across the width of the ship and support the decking planks which run from stem to stern of the ship.

“Also the piece that is checked out at the junction of the arms would have been required to fit over the beam shelf.”

It is upright as a 7 with the notch (7” x 3”) accommodating the beam shelf – i.e. 7” on the short arm & 3” on the long.

The distal notch is an anomaly – it would make sense if the 7 x 3 were 7” high & 3” deep as in the image of the Duyfken below. It is noted that the nut & bolt in the knee at left is similar to that of the artefact MH7. It was the opinion of Noel that there are too few bolts on the long arm and it would not have passed muster in Beattie's yard.

John Settree, see below, suggests that rather than a '7' it should be inverted as a reverse 'L' such that the long arm is against the hull and the sweep at the elbow respects the inward line of the ship's bottom.

Using the end-grain rubbing the diameter of the tree without bark = 310mm or 1 foot with large flying buttress roots.

The knee appears to have been partially dressed, perhaps by a power saw - the Beattie Yard had electricity with one saw and one drill.

Beattie's coastal woodland probably depleted. The Pat Cam's naval architect, Arthur Carlyle 'Ali' Barber, imported timber from New Zealand - a bankruptcy petition was brought against him by the Parker Lamb Timber Co. Ltd. of Onehunga NZ for non-payment of accounts on 7 March 1939.

Noel Riley’s observation “a beam knee & not a lodging knee because one of the arms is too long to sit between beams”.

This is not a lodging knee – the beams run across the width of the ship and support the decking planks which run from stem to stern of the ship.

“Also the piece that is checked out at the junction of the arms would have been required to fit over the beam shelf.”

It is upright as a 7 with the notch (7” x 3”) accommodating the beam shelf – i.e. 7” on the short arm & 3” on the long.

The distal notch is an anomaly – it would make sense if the 7 x 3 were 7” high & 3” deep as in the image of the Duyfken below. It is noted that the nut & bolt in the knee at left is similar to that of the artefact MH7. It was the opinion of Noel that there are too few bolts on the long arm and it would not have passed muster in Beattie's yard.

John Settree, see below, suggests that rather than a '7' it should be inverted as a reverse 'L' such that the long arm is against the hull and the sweep at the elbow respects the inward line of the ship's bottom.

Using the end-grain rubbing the diameter of the tree without bark = 310mm or 1 foot with large flying buttress roots.

|

|||||||||||||||||||

Rationale

HMAS Patricia Cam – Logic Cascade of MH7 Deposition

KNOWN

· The double skin hardwood bottom was blown out of her capacious hold such that those men who were sitting on the hatch covers & fell into the hold were immediately ejected by the ingress of water & they survived.

· The ship immediately lost way – she was heading north – the engines were cut to leave her with little & decaying forward momentum.

· She went down on an even almost keel by the bow (Meldrum testimony to Inquiry) – which continued until her top lift went below the surface.

· It was the middle of the Wet Season – middle of the day - calm seas with light airs.

· No wreckage of the vessel was seen by the men in the water – only cargo & furniture.

· No wreckage came ashore at the survivor camp island – only a melon.

· No wreckage of any kind was reported except for a large tank that was seen from the air & mistaken for an experimental mine.

· No other wreckage has ever been reported.

KNOWN

· The double skin hardwood bottom was blown out of her capacious hold such that those men who were sitting on the hatch covers & fell into the hold were immediately ejected by the ingress of water & they survived.

· The ship immediately lost way – she was heading north – the engines were cut to leave her with little & decaying forward momentum.

· She went down on an even almost keel by the bow (Meldrum testimony to Inquiry) – which continued until her top lift went below the surface.

· It was the middle of the Wet Season – middle of the day - calm seas with light airs.

· No wreckage of the vessel was seen by the men in the water – only cargo & furniture.

· No wreckage came ashore at the survivor camp island – only a melon.

· No wreckage of any kind was reported except for a large tank that was seen from the air & mistaken for an experimental mine.

· No other wreckage has ever been reported.

Deposition Hypothesis

After her double-skinned hardwood bottom, below the capacious hold (forward), was blown away - she sank within minutes.

· Her descent was by the bow, on an almost even keel, probably continued to the bottom without change at a shallow angle & slow descent.

· She hit the sandy flat bottom at c60ft whilst upright & slightly by the bow.

· She ploughed sand into her hold like a Scraper & came to rest already partially buried.

· Stuck fast on a shallow, featureless, flat sea floor she rapidly became entombed by sand.

· After 70 years her metal fixings corroded through - finally separating without major trauma.

· Wave action from a severe cyclone (e.g. Monica 2006) dislodged the beam knee.

· It travelled along the sea floor with the on-shore wave action at 90° to the beach.

· When near to the shore it was perhaps effected by the southerly current.

· It arrived at the high energy point of the beach & was stranded {placed on the strand line} by wave action.

OBSERVATION

MH7 is not burnt - being found on the strand line – not in the scrub - so safe from wildfire & white ants.

No Aboriginals have lived in the area for many decades so not lost to firewood.

There is evidence of surface scarring by Toledo worms unable to penetrate the timber suggesting a hardwood.

As the metal rod fixings are corroded to a point the wreck was substantially intact for a long period.

CONCLUSION

The wreck lies off Marchinbar at 90 degrees to the find site - in a 300 yard wide strip - corresponding to the mid-point of the beach to the north.

Other pieces of the wreck will come ashore near the same point.

· Her descent was by the bow, on an almost even keel, probably continued to the bottom without change at a shallow angle & slow descent.

· She hit the sandy flat bottom at c60ft whilst upright & slightly by the bow.

· She ploughed sand into her hold like a Scraper & came to rest already partially buried.

· Stuck fast on a shallow, featureless, flat sea floor she rapidly became entombed by sand.

· After 70 years her metal fixings corroded through - finally separating without major trauma.

· Wave action from a severe cyclone (e.g. Monica 2006) dislodged the beam knee.

· It travelled along the sea floor with the on-shore wave action at 90° to the beach.

· When near to the shore it was perhaps effected by the southerly current.

· It arrived at the high energy point of the beach & was stranded {placed on the strand line} by wave action.

OBSERVATION

MH7 is not burnt - being found on the strand line – not in the scrub - so safe from wildfire & white ants.

No Aboriginals have lived in the area for many decades so not lost to firewood.

There is evidence of surface scarring by Toledo worms unable to penetrate the timber suggesting a hardwood.

As the metal rod fixings are corroded to a point the wreck was substantially intact for a long period.

CONCLUSION

The wreck lies off Marchinbar at 90 degrees to the find site - in a 300 yard wide strip - corresponding to the mid-point of the beach to the north.

Other pieces of the wreck will come ashore near the same point.

Wood Analysis

"Thanks for sending a good size sample to work with. As you can see from the identification the wood is an Aglaia (genus) with over 100 species. The one (sapindina) I have suggested looks like it but there could be others which have identical structure and appearance. The species are very wide spread from Burma across to SE/Asia and the wood has been used for boat building. That pretty well excludes the Patricia Cam and your suggestion is consistent with the possibility that it could be from one of many unknown Indon/SE Asian shipwrecks.

I hope that the information is helpful for your project."

Re: Assessment of one wood specimen from a ships knee that was found on the Wessel Islands:

Following microscopic examination, in my opinion the structure of the wood specimens is consistent with1:

Sample Number Scientific name Commercial or Trade name+ Remarks

- Aglaia ?2 sapindina AGLAIA

I hope the information will help with your evaluation process.

Best regards, Jugo Ilic (Know Your Wood - [email protected])

I hope that the information is helpful for your project."

Re: Assessment of one wood specimen from a ships knee that was found on the Wessel Islands:

Following microscopic examination, in my opinion the structure of the wood specimens is consistent with1:

Sample Number Scientific name Commercial or Trade name+ Remarks

- Aglaia ?2 sapindina AGLAIA

I hope the information will help with your evaluation process.

Best regards, Jugo Ilic (Know Your Wood - [email protected])

Aglaia in Australia

|

Aglaia sapindina is a species of plant in the Meliaceae family. It is found in Australia (Northern Territory and Queensland), Indonesia, Papua New Guinea, and the Solomon Islands.

|

|

Below is a SNIP of the ALA website [http://biocache.ala.org.au/occurrences/search?q=Aglaia#tab_mapView] showing all records of Aglaia for Australia. There is a molluscan genus called Aglaia as well and that is the Sydney records.

There do not appear to be any Aglaia species native in NSW – see Australian Plant Census [https://biodiversity.org.au/nsl/services/apc] and PlantNET [the NSW eFlora - http://plantnet.rbgsyd.nsw.gov.au/search/simple.htm].

ALA – www.ala.org.au

Dr Marco Duretto - Manager Plant Diversity - National Herbarium of New South Wales

There do not appear to be any Aglaia species native in NSW – see Australian Plant Census [https://biodiversity.org.au/nsl/services/apc] and PlantNET [the NSW eFlora - http://plantnet.rbgsyd.nsw.gov.au/search/simple.htm].

ALA – www.ala.org.au

Dr Marco Duretto - Manager Plant Diversity - National Herbarium of New South Wales

The Timber Used

It is said that the Pat Cam was, unusually, constructed entirely of local hardwoods. There may have been a political element where the Government was promoting the resurgence of timber shipbuilding given the wartime shortage of steel. Between the wars timber ships had been discredited by the Americans who had used softwoods and not employed tween decks while adding ever heavier winches and machinery. I was likely a tactic of the steel industry in the same way as marijuana was vilified & hemp growing nations embargoed to destroy hemp rope as competition for Dupont nylon rope. Only wartime necessity brought a brief respite for hemp which is one of the most useful natural resources, grows in otherwise poor nations, e.g. Bangladesh.

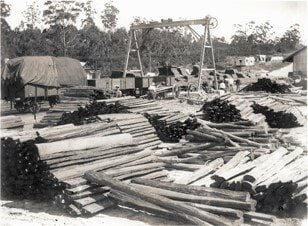

Alan told me re timbers used at the yard: “Crooks that form the shape, could be anything. The keels - ironbark and most of the frames were blackbutt, bluegum, white mahogany, ironbark, from the local bush around about. (Gwen Dundon)

|

Maple - not a full hardwood (John Settree)

Forest Oak Ironbark for roofing shingles & keels/keelsons Red Cedar for furniture Blue Gum, Blackbutt White Mahogany, Ironbark for frames Turpentine |

A 60ft trawler built by JL Boyd at Swansea & designed by AC Ali Barber was launched on February 1941. Mainly local hardwoods - 12" square Ironbark keel fastened with 7.8in. gunmetal screw bolts. The ribs are Ti-tree - joined with Oak dowels - planking of Blue Gum secured by gunmetal dumps. The deck is of Beech.

|

White Mahogany

White Mahogany

Yes, the knee is consistent with what I would expect to have seen in the Patricia Cam. I guess that it is a beam knee and not a lodging knee because one of the arms is too long to sit between beams. Also the piece that is checked out at the junction of the arms would have been required to fit over the beam shelf.

The vessel was fastened with hot dip galvanised steel bolts that were cut from long lengths of rod to the required length for each bolt. This fits in with the fastenings of the knee.

I remember the electricity going on as a gap was cut in the trees above Palermo that we could see from our house in Blackwall.

WBR

Noel Riley

The vessel was fastened with hot dip galvanised steel bolts that were cut from long lengths of rod to the required length for each bolt. This fits in with the fastenings of the knee.

I remember the electricity going on as a gap was cut in the trees above Palermo that we could see from our house in Blackwall.

WBR

Noel Riley

Hatch Covering

You can see hatch beams, about 6ft apart going in a transverse direction between the longitudinal hatch coamings.

The hatch beams supported hatch boards, made from 12in x 2 1/2in oregon. These would have had galvanised iron straps on the ends and two recessed handles made from about 1/2in diameter galvanised rod.

Two or three tarpaulins were then laid over the hatch boards. These hung over the side of the hatch coamings and were secured to the coamings with galvanised steel flat bars which were wedged in place to get a watertight joint for the tarpaulins.

When these were in place then two wire ropes would be laid diagonally across the hatch and tightened up with bottle screws to prevent the tarpaulins from lifting in the middle.

You can see hatch beams, about 6ft apart going in a transverse direction between the longitudinal hatch coamings.

The hatch beams supported hatch boards, made from 12in x 2 1/2in oregon. These would have had galvanised iron straps on the ends and two recessed handles made from about 1/2in diameter galvanised rod.

Two or three tarpaulins were then laid over the hatch boards. These hung over the side of the hatch coamings and were secured to the coamings with galvanised steel flat bars which were wedged in place to get a watertight joint for the tarpaulins.

When these were in place then two wire ropes would be laid diagonally across the hatch and tightened up with bottle screws to prevent the tarpaulins from lifting in the middle.

The Lump in the Middle

You will observe that there is a circle with a line through the diameter on that piece of timber. This is the load line mark or the Plimsol mark.

I think that the piece of timber may have been carved and then put into place when the load line had been determined.

If we could get better definition of the circle we would see two letters, e.g., LR or CA. If we could find out what they were then application could be made to the relevant authority to see if they had any drawings.

You will observe that there is a circle with a line through the diameter on that piece of timber. This is the load line mark or the Plimsol mark.

I think that the piece of timber may have been carved and then put into place when the load line had been determined.

If we could get better definition of the circle we would see two letters, e.g., LR or CA. If we could find out what they were then application could be made to the relevant authority to see if they had any drawings.

Building the Pat Cam

Gwen Dundon - I went through my notes again from when I visited the late Allan Davis [mentioned before] and the following is a part that might be relevant to your question:

“We used to make a mould, and the job was given to two local chaps [both deceased] ......................They would go out in the bush, look around until they saw a branch or part of a tree growing approx the shape of the mould. Now they would cut that, fetch it down into the yard and we would side it with an axe, shape it with an adze, put it together. Might take three or four pieces to get half of that mould, whatever it was, of the ship. That was doubled, because each time there was a joint, there would be a piece lapping over the same shape. This is an interesting part of ship work, because not too many ships are done that way today. They are nearly all bent frames or bent ribs. The pieces were made with what was known as “dumps” or bolts in other words, of steel, copper or brass. Called “dumps”, they were a driving bolt. They [the sections] were put together erected, a bit of moulding put all around to hold them together.......

Allan, who was a carpenter and joiner, told me that at the time the yard built PC, Gordon Beattie was retired, but would come out of his house above the job several times a day to eye the work, suggest a bit off here, a bit off there, and because he had a marvellous “eye” for line, was always right. When it was decided to built PC, Allan was working to the order of Man Power in a munitions factory. He was asked if he would go and work on the war vessels at Beatties for the Civil Construction Corps, and not surprisingly, he agreed.

It is thought-provoking, don’t you feel: – that the launching of this vessel was a debacle. I have always believed that tradition held such a happening meant bad luck for the ship.

By the way, there is a puzzling variation in the records of PC. Newspapers at the time of her imminent construction, and later, called her a “trawler” for Lake Macquarie where the family had fishing interests. The official register states she was a collier. I brought up the matter with Allan and he remarked that she had a huge hold – they would play cricket in their meal breaks – and the stern would have been impossible for trawling nets to be used. She did have a large freezing compartment, and it was conjectured that the Cams intended to transport some fish, as well as coal.

“We used to make a mould, and the job was given to two local chaps [both deceased] ......................They would go out in the bush, look around until they saw a branch or part of a tree growing approx the shape of the mould. Now they would cut that, fetch it down into the yard and we would side it with an axe, shape it with an adze, put it together. Might take three or four pieces to get half of that mould, whatever it was, of the ship. That was doubled, because each time there was a joint, there would be a piece lapping over the same shape. This is an interesting part of ship work, because not too many ships are done that way today. They are nearly all bent frames or bent ribs. The pieces were made with what was known as “dumps” or bolts in other words, of steel, copper or brass. Called “dumps”, they were a driving bolt. They [the sections] were put together erected, a bit of moulding put all around to hold them together.......

Allan, who was a carpenter and joiner, told me that at the time the yard built PC, Gordon Beattie was retired, but would come out of his house above the job several times a day to eye the work, suggest a bit off here, a bit off there, and because he had a marvellous “eye” for line, was always right. When it was decided to built PC, Allan was working to the order of Man Power in a munitions factory. He was asked if he would go and work on the war vessels at Beatties for the Civil Construction Corps, and not surprisingly, he agreed.

It is thought-provoking, don’t you feel: – that the launching of this vessel was a debacle. I have always believed that tradition held such a happening meant bad luck for the ship.

By the way, there is a puzzling variation in the records of PC. Newspapers at the time of her imminent construction, and later, called her a “trawler” for Lake Macquarie where the family had fishing interests. The official register states she was a collier. I brought up the matter with Allan and he remarked that she had a huge hold – they would play cricket in their meal breaks – and the stern would have been impossible for trawling nets to be used. She did have a large freezing compartment, and it was conjectured that the Cams intended to transport some fish, as well as coal.

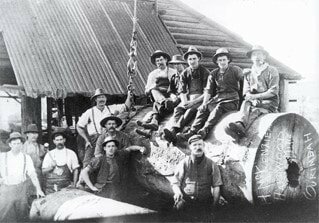

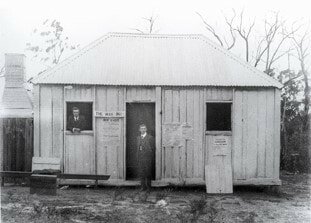

The History of Brisbane Water Timber - Gosford Library

Early Industry in Brisbane Water. One of the earliest industries in the Brisbane Water district was that of collecting shells for lime manufacture. Shells mined from natural shell banks and aboriginal middens were transported to Sydney for burning. Lime obtained in this way was used in mortar for building.

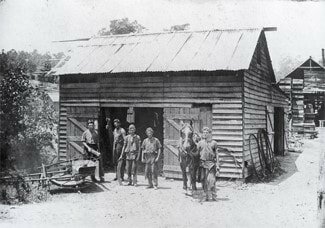

Shipbuilding was centred around Blackwall, Kincumber, Green Point, Empire Bay, Davistown, Erina Creek and Terrigal. Early shipbuilders of the district included Robert Henderson of Saratoga, Jonathan Piper of Kincumber and the four Davis brothers, Ben, Thomas, Rock and Edward. Shipbuilding continued using local timber into the 20th century.

Timber-getters worked in the hills to obtain forest oak and ironbark for roofing shingles. Red Cedar was in high demand for furniture manufacture. Cedar getting began in 1820 and continued, to peak in 1830.

Shipbuilding was centred around Blackwall, Kincumber, Green Point, Empire Bay, Davistown, Erina Creek and Terrigal. Early shipbuilders of the district included Robert Henderson of Saratoga, Jonathan Piper of Kincumber and the four Davis brothers, Ben, Thomas, Rock and Edward. Shipbuilding continued using local timber into the 20th century.

Timber-getters worked in the hills to obtain forest oak and ironbark for roofing shingles. Red Cedar was in high demand for furniture manufacture. Cedar getting began in 1820 and continued, to peak in 1830.

Shipbuilding. Brisbane Water was a cradle of early shipbuilding, with over 500 named vessels being built between 1829-1953. In its heyday, the local shipbuilding industry was second only to Sydney in terms of tonnage built.

The Brisbane Water shipbuilders influenced this trade right along the NSW coast, and their products were a mainstay of the eastern Australian coastal trade. The vessels built at Brisbane Water carried huge quantities of shells for lime manufacture needed for the building of Sydney, and thousands of tons of timber for wharf pilings, railway sleepers, mine props etc. to feed the States economic growth.

The Brisbane Water shipbuilders influenced this trade right along the NSW coast, and their products were a mainstay of the eastern Australian coastal trade. The vessels built at Brisbane Water carried huge quantities of shells for lime manufacture needed for the building of Sydney, and thousands of tons of timber for wharf pilings, railway sleepers, mine props etc. to feed the States economic growth.

Timber. In the early years timber-getters worked in the hills to obtain forest oak and ironbark for roofing shingles. Red Cedar was in high demand for furniture manufacture. Cedar getting began in 1820 and continued, to peak in 1830. Henry Donnison of Erina was one of the early fathers of the local timber industry. Donnison saw in the huge blue gum, turpentine and blackbutt trees the possibilities of large-scale timber getting.

Up to 50 assigned convict servants were employed on Donnison's lands, many as pit-sawyers. Logs were felled and dragged by bullocks and chains to a sawpit close by. Men worked in pairs, with team comprising a top man and a pit man. A long crosscut saw was used. Sawing logs in this way was a very hot, slow, dirty and dangerous process.

In early times local timber mills provided weatherboards, laths (small strips of timber used in walls and ceilings, providing a base for plastering) and shingles for roofing. http://www.centralcoastaustralia.com.au/profile.asp?ID=3500&pid=&confirm=yes&panel=enquiry

Up to 50 assigned convict servants were employed on Donnison's lands, many as pit-sawyers. Logs were felled and dragged by bullocks and chains to a sawpit close by. Men worked in pairs, with team comprising a top man and a pit man. A long crosscut saw was used. Sawing logs in this way was a very hot, slow, dirty and dangerous process.

In early times local timber mills provided weatherboards, laths (small strips of timber used in walls and ceilings, providing a base for plastering) and shingles for roofing. http://www.centralcoastaustralia.com.au/profile.asp?ID=3500&pid=&confirm=yes&panel=enquiry

Possibilities

Macassan Prau Sampson Post 1890s

Macassan Prau Sampson Post 1890s

Any ships' timber found in the NT is immediately dismissed as being from Indonesian fishing vessels captured during the last 40 years. It is widely believed that no timber survives because it is destroyed in the water by Toledo worms or burned if it reaches the shore.

The non-existence of North Australian history is readily proven by denying the existence of evidence. It is a self-fulfilling prophecy for heritage sceptics , axiomatically the absence of evidence is evidence of absence. Perhaps Ignorance of Evidence is Evidence of Ignorance. Any unusual object is a discarded souvenir from a boozy Bali holiday - it is a dangerous orthodoxy that stifles enquiry and makes a virtue of ignorance.

The Holy Grail of NT maritime archaeology is a Macassan Prau wreck. None have been found although nobody appears to have actually looked and this is defended by the orthodoxy that nothing survives. The image shows part of a 'Sampson' or belaying post from a Macassan prau in the days of the trade. It comes from a mid 1890's wreck that was document by a passing vessel.

The timber is of SE Asian origin, it has been attacked by the worms and it has been partially burned which has preserved it. It lay in the 'goldilocks zone above the water line & worms but below the line of fire and white ants as does the Macassan weir on Melville Island.

The submerged forest reef off Lee Point; the coastal woodland & later mangrove remains at Dundee Beach are examples of the preservative qualities of the anaerobic mud of the intertidal zone.

The non-existence of North Australian history is readily proven by denying the existence of evidence. It is a self-fulfilling prophecy for heritage sceptics , axiomatically the absence of evidence is evidence of absence. Perhaps Ignorance of Evidence is Evidence of Ignorance. Any unusual object is a discarded souvenir from a boozy Bali holiday - it is a dangerous orthodoxy that stifles enquiry and makes a virtue of ignorance.

The Holy Grail of NT maritime archaeology is a Macassan Prau wreck. None have been found although nobody appears to have actually looked and this is defended by the orthodoxy that nothing survives. The image shows part of a 'Sampson' or belaying post from a Macassan prau in the days of the trade. It comes from a mid 1890's wreck that was document by a passing vessel.

The timber is of SE Asian origin, it has been attacked by the worms and it has been partially burned which has preserved it. It lay in the 'goldilocks zone above the water line & worms but below the line of fire and white ants as does the Macassan weir on Melville Island.

The submerged forest reef off Lee Point; the coastal woodland & later mangrove remains at Dundee Beach are examples of the preservative qualities of the anaerobic mud of the intertidal zone.

Indonesian boat - AFMA image

Indonesian boat - AFMA image

The Indonesian fishing vessel is the default origin of all ships' timbers. They were numerous, highly publicised and were given the St Joan treatment by a Government anxious to give the impression that it could police our northern waters. The presence of Indonesian camps, nets & detritus in the Wessels Islands in 2013 demonstrates the reality. Despite older examples being of teak, these are crude but robust craft and some were seized & burned at Gove and in the islands to save the expense of dragging them back to Darwin for the public spectacle.

The distinguishing features of these craft are the fixings which are very crude and almost exclusively held together with concrete reinforcing bar 'reo' which is available, strong, cheap and adjustable with a lump hammer. These vessels didn't have much except buoyancy so the NT shores are not littered with wreckage. Also they did not travel alone.

The key elements of MH7 are the fixings and the fact that they are corroded through, separation occurred without trauma of fire or tempest to a wreck that had probably been submerged in saltwater for many decades.

The distinguishing features of these craft are the fixings which are very crude and almost exclusively held together with concrete reinforcing bar 'reo' which is available, strong, cheap and adjustable with a lump hammer. These vessels didn't have much except buoyancy so the NT shores are not littered with wreckage. Also they did not travel alone.

The key elements of MH7 are the fixings and the fact that they are corroded through, separation occurred without trauma of fire or tempest to a wreck that had probably been submerged in saltwater for many decades.

Questions

The proximal notch, which might be expected to hold the beam shelf, is 7''W x 3"H when the opposite would be expected 7"H x 3"W.

If reversed the long arm would fit under the deck and the short arm against the side of the ship.

Alternatively, if it fits as held by John Settree - the notch seems odd but the champher above the notch might match the start of the bottom.

The hatch had a large beam of steel across the centre - perhaps this required special support.

Perhaps the hold was lined to make coal extraction easier with the mechanical grab.

The style of MH7 is fine for the period and could be somewhat older.

Would MH7 float in saltwater?

The Pat Cam had one large hold - provision for refrigeration - a large capstan engine at the top-lift mast & below it a cockroach-ridden forecastle. The knee is very strong (semi-hardwood at least) so did it meet a specific need from these

According to the wood expert the timber is not right but according to all experts the fixings are right & they are definitely not of SE Asian type.

The number of bolts on the drop arm is too few for a Brisbane Water yard - Noel Riley.

The rods are iron - threaded - washer as spacers with a hexagonal nut as used at Beattie's yard - Noel Riley.

Would they have been used on other vessels - one of which has survived?

Would the metal fixing have been approved by a regulatory agency?

Would XRF or XRD of the metal provide a useful signature?

They cannot be conserved without removal from the knee - is this justified?

If reversed the long arm would fit under the deck and the short arm against the side of the ship.

Alternatively, if it fits as held by John Settree - the notch seems odd but the champher above the notch might match the start of the bottom.

The hatch had a large beam of steel across the centre - perhaps this required special support.

Perhaps the hold was lined to make coal extraction easier with the mechanical grab.

The style of MH7 is fine for the period and could be somewhat older.

Would MH7 float in saltwater?

The Pat Cam had one large hold - provision for refrigeration - a large capstan engine at the top-lift mast & below it a cockroach-ridden forecastle. The knee is very strong (semi-hardwood at least) so did it meet a specific need from these

According to the wood expert the timber is not right but according to all experts the fixings are right & they are definitely not of SE Asian type.

The number of bolts on the drop arm is too few for a Brisbane Water yard - Noel Riley.

The rods are iron - threaded - washer as spacers with a hexagonal nut as used at Beattie's yard - Noel Riley.

Would they have been used on other vessels - one of which has survived?

Would the metal fixing have been approved by a regulatory agency?

Would XRF or XRD of the metal provide a useful signature?

They cannot be conserved without removal from the knee - is this justified?